Geotechnical Construction News

- All

- Anchored Soldier Pile Walls

- Anchors

- Auger Cast Piles

- Driven Soil Nail Walls

- Leadership

- Micropiles

- Safety

- Secant Pile Wall

- Soil Nail Walls

- Soil Nailing

- Soldier Pile Walls

Auger Cast Pile Design

By TJ Ju, P.E. |

Step-by-Step Design Process of Auger Cast Piles (ACP) The design process for Auger Cast Piles (ACP) follows a ...

Read More Support of Excavation in Cities

By Jeffrey W. Coonse, PE |

Construction projects are ubiquitous in the busy concrete jungles that characterize modern cities. Whether it's the erection of ...

Read More Permanent Soil Nail Wall Face Options

By Jeffrey W. Coonse, PE |

Soil Nail face Options While we love soil nail walls and beauty is in the eye of the ...

Read More 3 Excavation Shoring Buy-out Pitfalls

By Jeffrey W. Coonse, PE |

General Contractors have a huge responsibility when buying out the many trades. Excavation shoring can be difficult as ...

Read More 5 Mistakes Contractors Make with Deep Excavations

By Jeffrey W. Coonse, PE |

Deep Excavation Mistake #1. You get 4' for free. OSHA tricked us. It's really not our fault. Everywhere ...

Read More Limited Access Micropiles, 180′ Deep

By Jeffrey W. Coonse, PE |

Limited Access Micropiles, Company Record 180' Depth As the 17-story Virginia General Assembly Building (VAGA) neared completion, it ...

Read More Anchors

By Jeffrey W. Coonse, PE |

Anchor design and installation for excavation support systems Definition FHWA defines anchors as cement grouted prestressed steel tendons ...

Read More Soldier Pile Wall Safety

By Jeffrey W. Coonse, PE |

What are some safety considerations when constructing soldier pile walls? Soldier pile wall safety is about taking care ...

Read More Soldier Pile Wall Construction

By Jeffrey W. Coonse, PE |

How are soldier pile walls constructed? Soldier Pile Installation Soldier piles are typically steel H-piles or W sections. ...

Read More Soldier Pile Wall Advantages

By Jeffrey W. Coonse, PE |

What are the advantages of a soldier pile wall? Flexibility Soldier Pile Walls are the go-to excavation shoring ...

Read More Quality Control for Micropiles

By Jeffrey W. Coonse, PE |

Micropile Foundation Quality Control Using some basic micropile foundation quality control measures will help your project move forward ...

Read More Micropile Design

By Jeffrey W. Coonse, PE |

Micropile Design Micropile design includes structural and geotechnical design. Let's discuss the importance of these two types of ...

Read More Micropile Advantages

By Jeffrey W. Coonse, PE |

What are the advantages of micropiles? Overcoming Difficult Ground Conditions The first advantage of micropiles has to do ...

Read More Quality Control for Soil Nail Walls

By Jeffrey W. Coonse, PE |

Soil Nail Walls Quality Control One of our founders has a saying, “checking is cheap.” Another one most ...

Read More How Does a Soil Nail Wall Work?

By Jeffrey W. Coonse, PE |

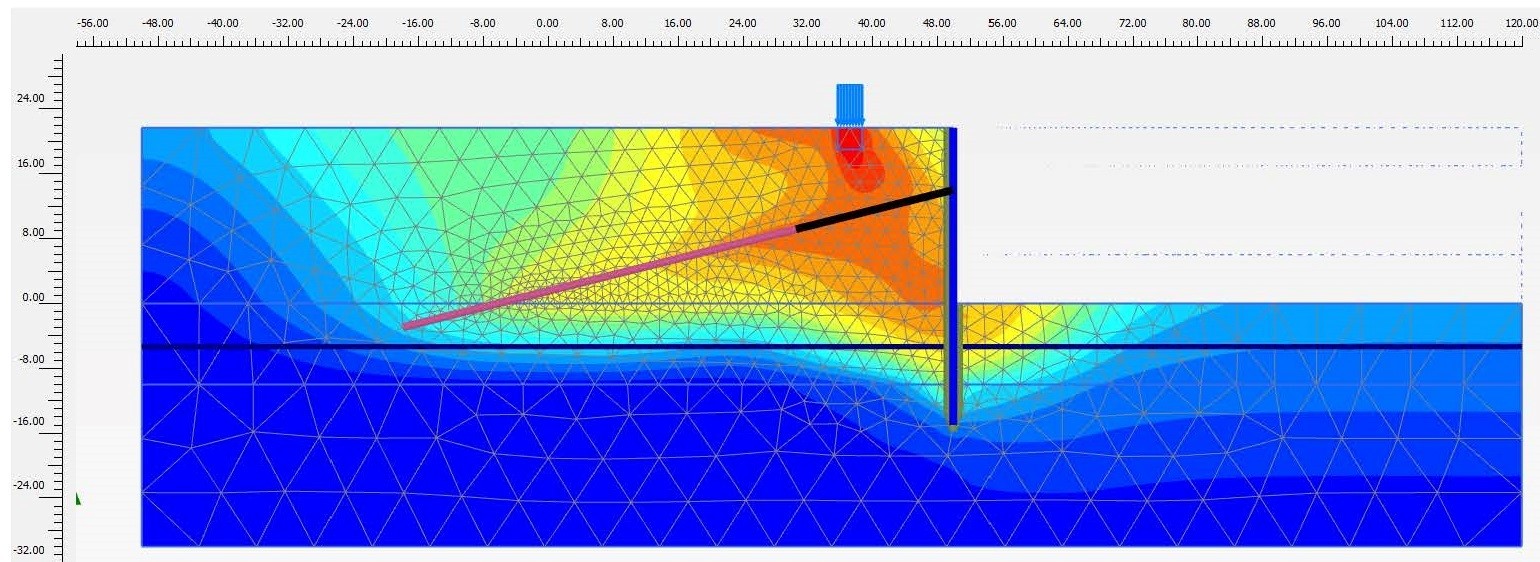

How does a soil nail wall work? Concept Soil nail walls are typically designed using a limit equilibrium ...

Read More Alex Smith is the New Managing Member

By Jeffrey W. Coonse, PE |

Congratulations to Alex Smith on becoming the new Managing Member at Subsurface Construction. Alex is a professional engineer, ...

Read More Soil Nail Wall Advantages

By Jeffrey W. Coonse, PE |

What are the advantages of a soil nail wall? Speed and Cost Soil nail walls are installed more ...

Read More Congratulations to Greg Sullivan

By Jeffrey W. Coonse, PE |

With admiration, gratitude, and sadness we announce that Greg Sullivan will retire at the end of 2020. Greg ...

Read More Permanent or Temporary Soil Nail Wall?

By Jeffrey W. Coonse, PE |

Do you need a permanent or temporary soil nail wall? Here are the similarities and differences. Both Remain ...

Read More Empathy is Imperative – Construction Leadership

By Jeffrey W. Coonse, PE |

Expressing genuine empathy is critical to being a successful leader, salesperson and coworker. Want to lose someone's confidence? ...

Read More OSHA Announces “Targeted Industries in Construction” for silica enforcement.

By Jeffrey W. Coonse, PE |

Silica Enforcement in the Construction Industry We should consider the OSHA's new silica law a good thing. The ...

Read More Considering Movement of Excavation Shoring Systems

By Jeffrey W. Coonse, PE |

Considering Movement of Excavation Shoring Systems Are you shoring to limit excavation into a tree protection area? Are ...

Read More Robert Jones Serves as Field Supervisor for AMPIS Drilling School

By Jeffrey W. Coonse, PE |

We would like to recognize our General Superintendent, Robert Jones, for serving as Field Supervisor for the Anchor ...

Read More The things we (and you) should ask when Preparing and Evaluating a Shoring Bid

By Joseph Nixon, PE |

Common questions we ask ourselves when preparing a shoring bid: 1.Have we clearly communicated the scope of work ...

Read More Leading Engineer TJ Ju becomes a US Citizen

By Jeffrey W. Coonse, PE |

Congratulations to TJ Ju, PE, on becoming a US Citizen. TJ is our lead geotechnical design engineer, a ...

Read More Micropile Foundations – Are they a good fit for this project?

By Jeffrey W. Coonse, PE |

Micropile Foundations Is this project a good fit for micropiles? This is a question that I’m asked quite ...

Read More Are you a Level 5 Leader?

By Jeffrey W. Coonse, PE |

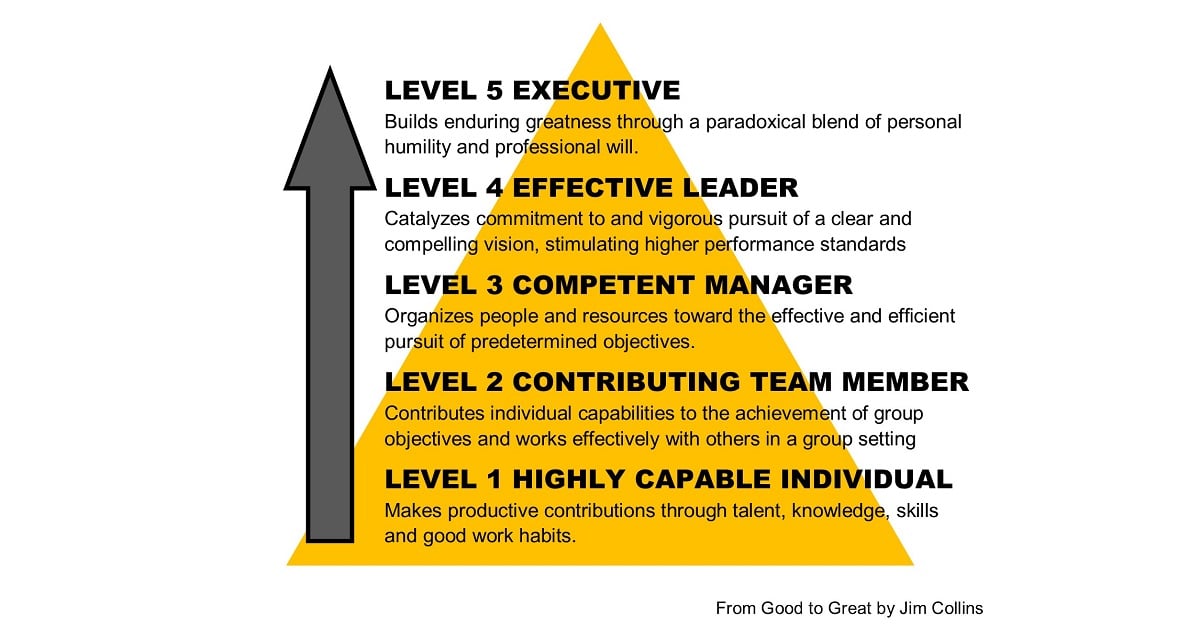

Leading in the Construction Industry HUMILITY + WILLJim Collins in "Good to Great" defines Level 5 Leaders as ...

Read More Why you should use driven soil nails.

By Jeffrey W. Coonse, PE |

https://www.subsurfaceconstruction.com/wp-content/uploads/2018/09/Why-you-should-use-driven-soil-nails.mp4

Read More Silica Exposure Control Programs in the Drilling Industry

By Jeffrey W. Coonse, PE |

Silica Exposure Control Programs in the Drilling Industry We are all gaining familiarity with “Table 1. SPECIFIED EXPOSURE ...

Read More Leadership Development

By Joseph Nixon, PE |

Recently our Regional Managers, Alex Smith, PE and Jodie Nixon, PE, attended the Bell Leadership Institute’s Achievers™ conference in ...

Read More VA War Memorial featured in Foundation Drilling Magazine

By Greg Sullivan, PE |

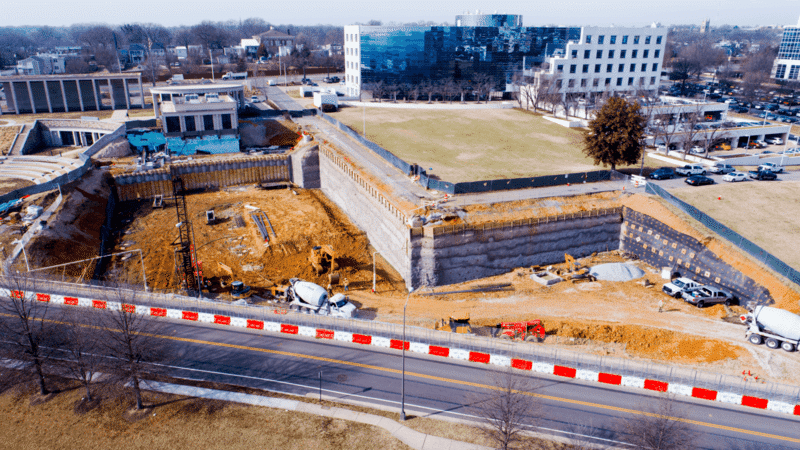

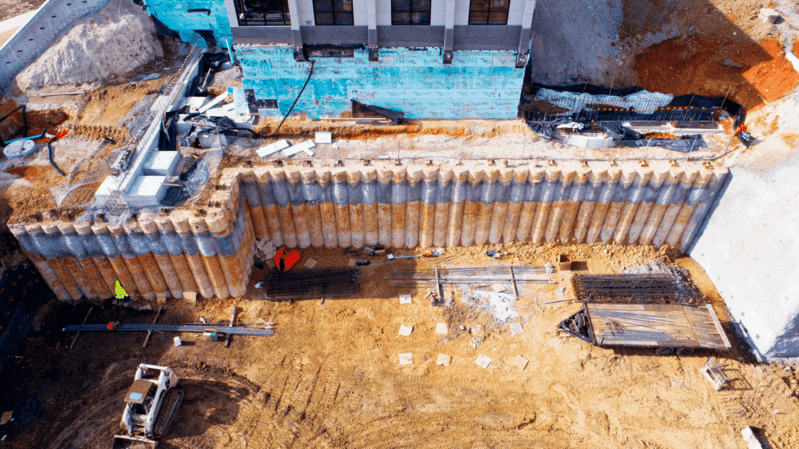

Subsurface Construction is honored to have the Virginia War Memorial as a Technical Featured article in Foundation Drilling ...

Read More Secant Pile Wall

By Jeffrey W. Coonse, PE |

Subsurface completed a permanent secant pile wall at the VA War Memorial. The wall serves as a permanent ...

Read More First driven soil nail wall is allowed in Fairfax County, VA

By Jeffrey W. Coonse, PE |

Driven soil nail wall innovation benefits client in McLean, VA. For the Freddie Mac Expansion project in McLean, ...

Read More Subsurface Helps Develop Senior Community Site

By Jeffrey W. Coonse, PE |

Developer taps into demand created by Triangle’s growing senior population DAVID BRACKEN RALEIGH With the Triangle’s job market ...

Read More Drilling Safety – Always Critical

By Jeffrey W. Coonse, PE |

I am sharing an email from one of our industry safety leaders: All, This is yet another unfortunate ...

Read More