General Contractors have a huge responsibility when buying out the many trades. Excavation shoring can be difficult as some GCs may only hire this trade once a year. Buy-out gets more tricky in a tough economy. Unscrupulous subcontractors are tempted to push hidden risks onto the GC in hopes of having the low number. Honest subcontracts may have difficulty communicating these risks to their clients. The best we can do as a construction community is to make honest assumptions and state those assumptions clearly.

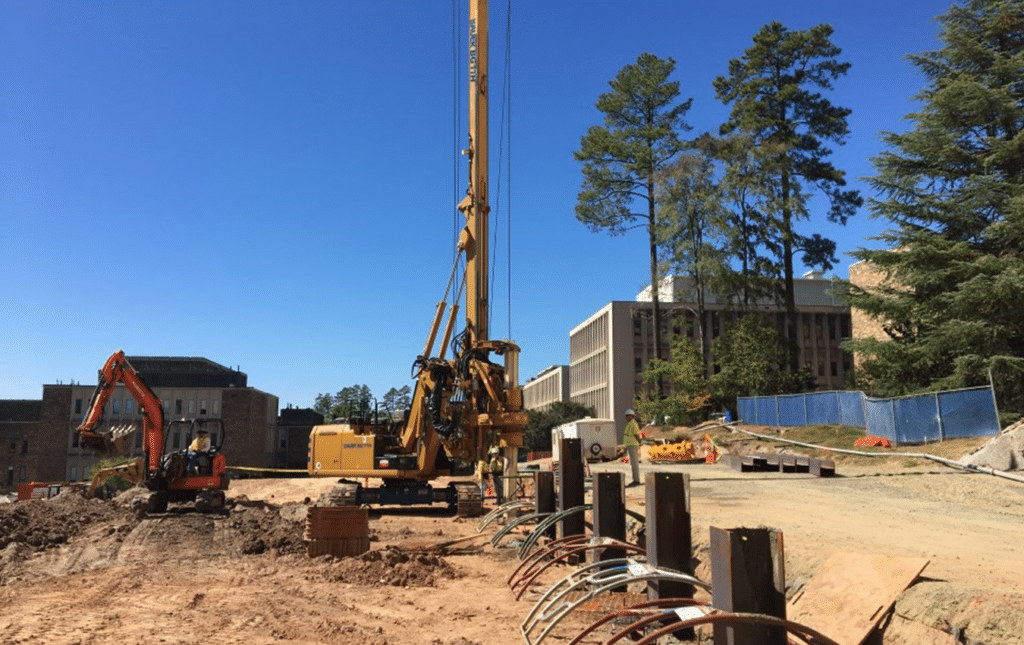

Open hole drilling

We often state open hole drilling in our proposals. Most residual soils above the water table can be drilled without the need for casing or slurry to keep the hole open. For example, soil nail walls are bid assuming open-hole drilling. However, when drilling in sandy material below the water table, open hole drilling may be a bad assumption. Often anchors in poor fill or coastal soils must be fully cased with the casing extracted as the hole is tremie grouted. It is imperative for the subcontractor to use their experience to provide a reasonable assumption of drilling conditions.

open hole drilling: Drilling without the need for casing or slurry. The drill hole remains open until the reinforcing bar and grout are installed.

Conventional auger drilling

Drilling with augers and assuming you will not hit refusal can be the trickiest of these assumptions. Successful auger drilling depends on strength of the drill rig used and the quality of the auger head and drill teeth. Rigs with huge torque and crowd (downward force) matched with a rock auger can make good progress through hard material. This often requires local experience with the ground conditions. Some soil types are easier to auger than others that have the same SPT values (blow counts).

conventional auger drilling: Drilling with augers to reach the bottom of the proposed elevation without refusing on rock.

Shotcrete overage

When bidding any project with a shotcrete face, the subcontractor must assume a volume of shotcrete overage. The volume of shotcrete required is a function of how neatly the ground is trimmed at the back of the shotcrete. In soil, common assumptions for shotcrete overage may be in the 30% range. When placing shotcrete in partially weathered rock (PWR) or rock, the volume of shotcrete required increases.

The biggest determinate in shotcrete overage in rock is the quality of the blasting program. Line drilling is often done to provide a break line for the blasting energy. In line drilling, 3″ to 4″ holes are typically drilled at 12″ on center along the back of the proposed shotcrete face. These holes are generally not loaded with charges. The line drilling forms a “break line” where blasting gases can escape and reduce over blasting the shored face. Of course, the spacing, timing, and loading the holes in front of the line drilling also play a role.

shotcrete overage: The percentage of additional shotcrete volume over the amount required for the dimensions of the wall (area x design thickness)

Extra credit