What is a micropile?

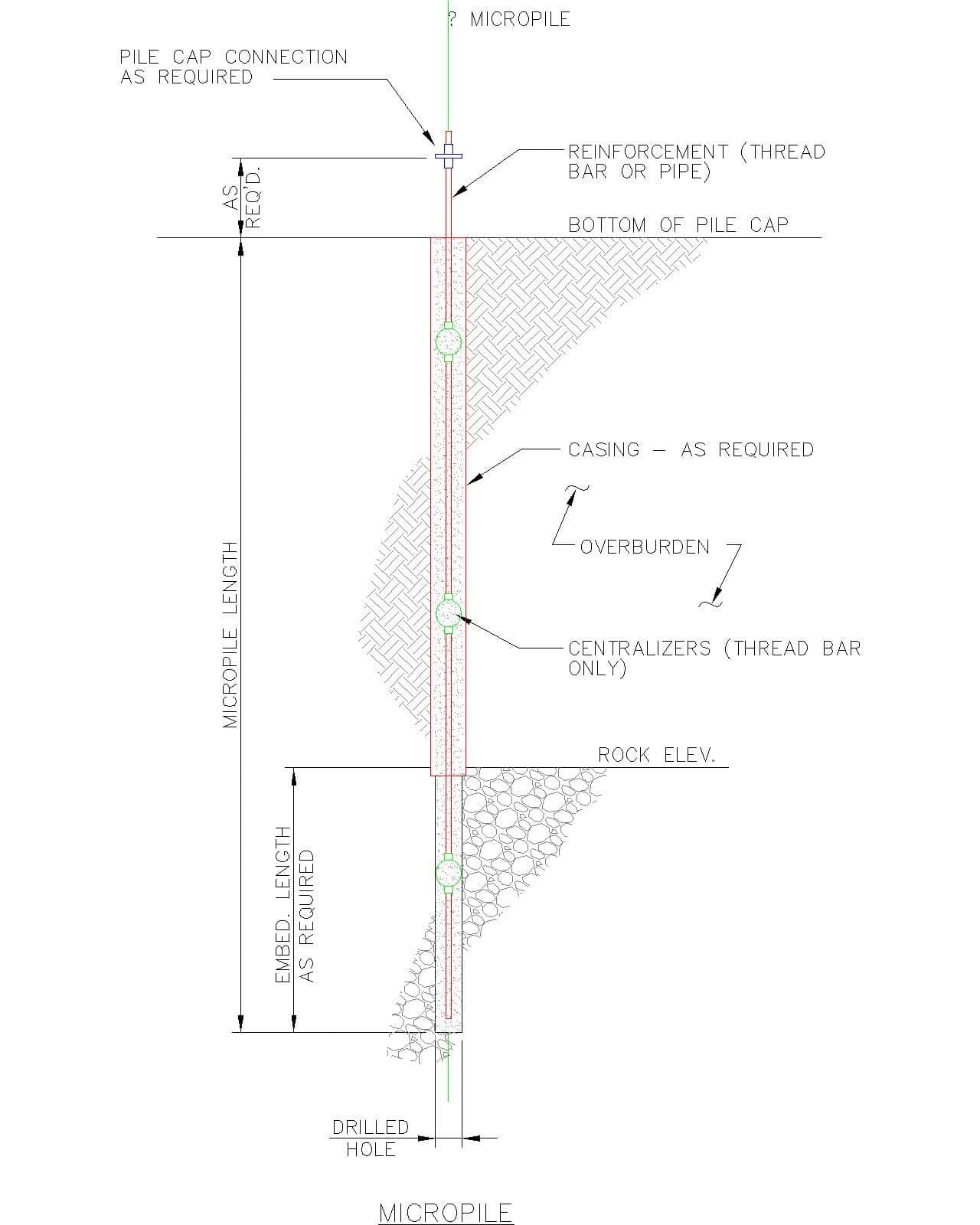

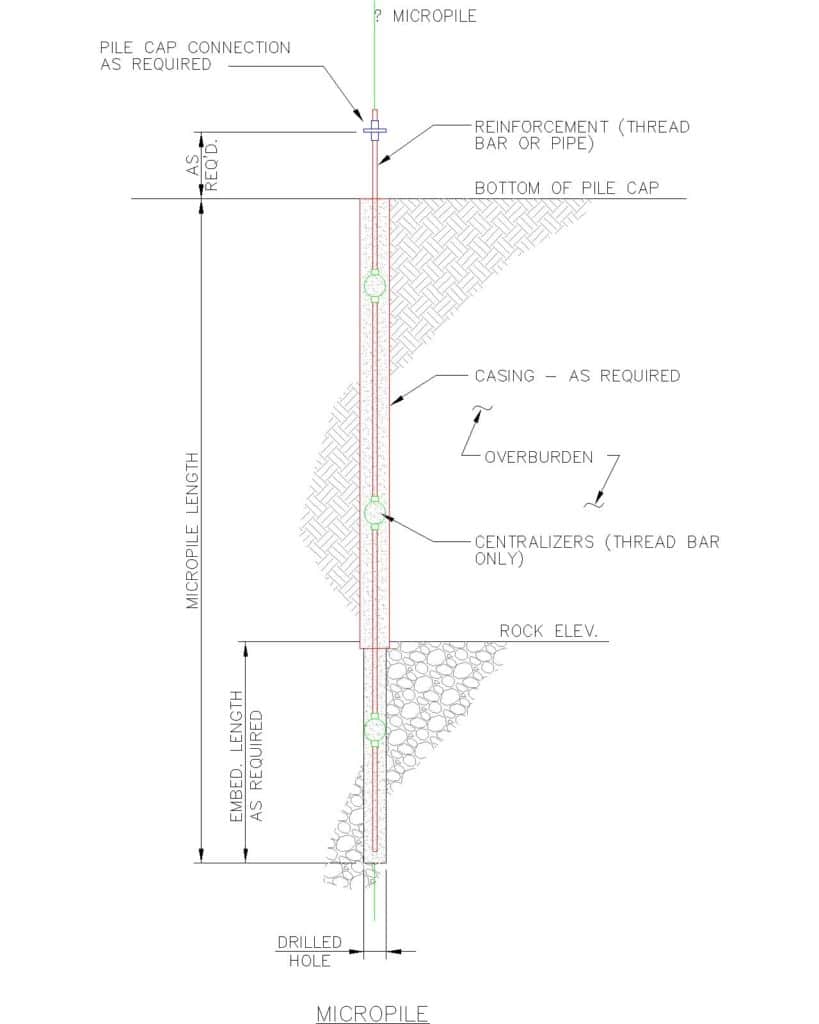

A micropile is a high capacity small diameter pile that can be installed through difficult soil conditions and in limited access. Micropiles are typically installed by advancing casing pipe to rock, drilling a rock socket, then grouting reinforcing steel in the rock socket.

In spite of their small diameter, less than 12″, micropiles capacities typically range from 100 kips to 400 kips.

Advantages

- Micropiles can be installed through boulders and debris. Unlike other deep foundations, contractors can use overburden drilling systems that cut ahead of the casing to get through very hard boulders and concrete debris.

- Micropiles are the best deep foundation system in challenging karst geology. Karst is water soluble rock. In Subsurface Construction’s service area, karst is found in the mountains of Virginia and eastern Tennessee. Because karst contains layers of hard rock and soft soil or voids, micropiles can be cased through the soft zones to competent rock.

- Micropiles are ideal in limited access areas such as basements. The piles are often used to underpin failing foundations or to support new columns for vertical expansions. 400 kip piles can be installed in 9-feet of headroom. Contractors can use equipment that is powered by electricity or hydraulic power packs stored outside the building to avoid introducing fumes inside the existing building.

Is my project a good fit for micropiles?

Limitations

- Due to their small diameter, typically 6″ to 12″, vertical micropiles have limits in resisting lateral loads. One solution is the embed the piles 2 diameters into the pile cap to create a fixed-head condition, cutting the lateral deflection in half in comparison to a free-head condition. Another option is to batter some of the micropiles. 1/4(H):1(V) or 15 degree batters are typical. The battered piles are then able to use the resultant horizontal force to resist lateral loads.

- Micropiles are the most economic and sometimes only solution in difficult ground conditions and limited access. For sites that have more homogenous soil profiles, other foundations such as auger cast piles or driven piles are preferred.

Construction

Micropiles are constructed by advancing casing through the overburden soil to the top of rock. The casing is threaded together in sections as the piles are advanced. Once the top or rock is reached, a hole is drilled in rock with a bit that fits inside the casing. The rock socket is an open hole in rock that is typically 5″ to 8″ diameter depending on the casing size and pile capacity needed. Rock sockets are 5′ to 20′ or more in length depending on the quality of the rock and the pile capacity. Once the casing has been advanced to rock, the inner drill rod, down hole hammer, and bit are extracted leaving the cased hole and open rock socket. Steel reinforcement is then lowered through the casing and into the rock socket. The hole is then tremie grouted displacing any ground water. The grout bonds the reinforcing steel to the rock socket, provides corrosion protection, and assists the steel in carrying compression load.

- Duplex drill casing through the overburden soil to the top of rock.

- Continue drilling without the casing to make the rock socket.

- Extract the drill steel, down hole hammer, and bit.

- Lower reinforcing steel (typically a threaded rod) into the casing and rock socket.

- Tremie grout the full length of the pile.

Learn more about QC of Micropiles

Design

The majority of the compression load is carried by steel with a contribution from the grout. Micropile design is governed by two main bodies, the FHWA and International Building codes. The structural capacity is determined by combining the allowable contribution of the steel and grout.

FHWA NHI-05-039 December 2005

0.47*Asteel*Fy-steel + 0.40*Agrout*fc-grout = Compression Capacity

IBC 2015

0.40*Asteel*Fy-steel + 0.30*Agrout*fc-grout = Compression Capacity

Note that Fy-steel is limited to a maximum of 87 ksi.

Other Resources

FHWA Micropile Manual

IBC 2015 Chapter 18 Deep Foundations

Guide to Drafting a Specification for Micropiles

Photos