Deep Excavation Mistake #1. You get 4′ for free.

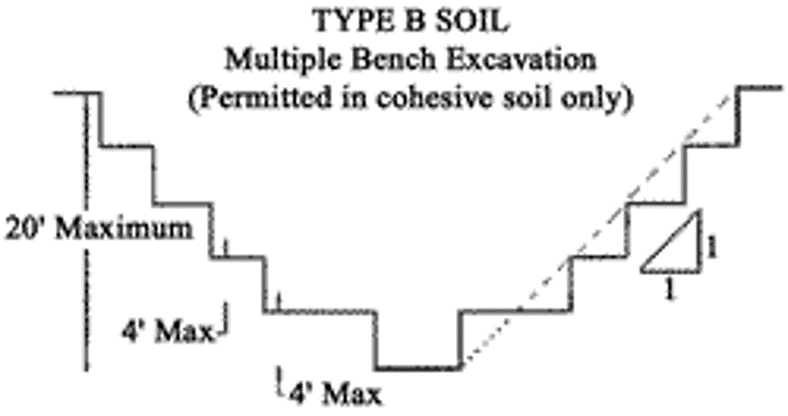

OSHA tricked us. It’s really not our fault. Everywhere I go, in every deep excavation I visit, most contractors think they get 4 feet for free? Right? Don’t we? Unfortunately, no. Where did this get started? I believe it’s from the OSHA benching sketch.

It sure looks like 4′ at the bottom. The problem is that the excavation then steps out 8′ horizontally before continuing the benching at a 1:1 angle. OSHA requires that your excavation angle be measured from the lowest point to the top. In order to have a 20′ deep excavation in Type B soil, contractors need 20′ of horizontal space for layback.

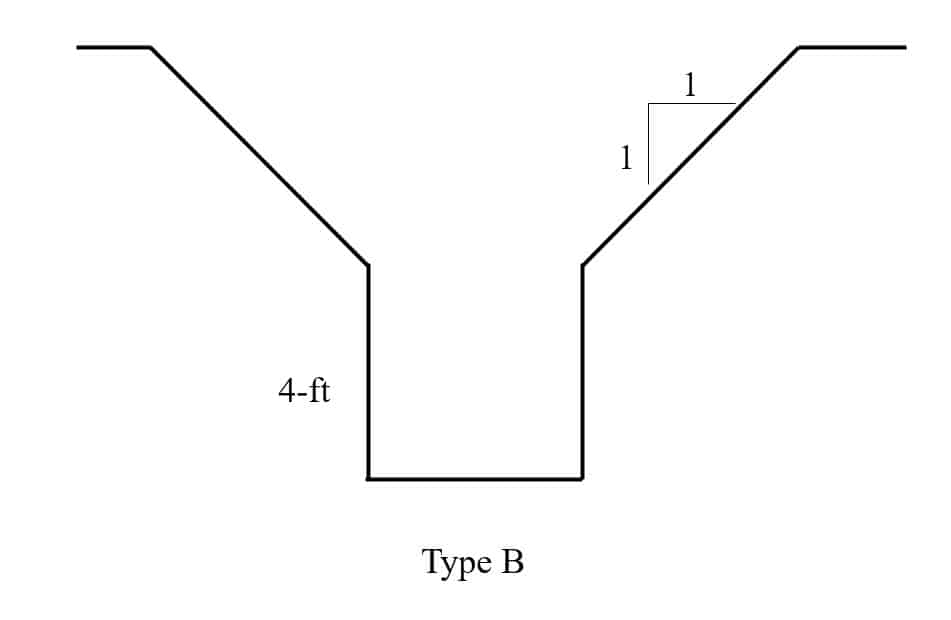

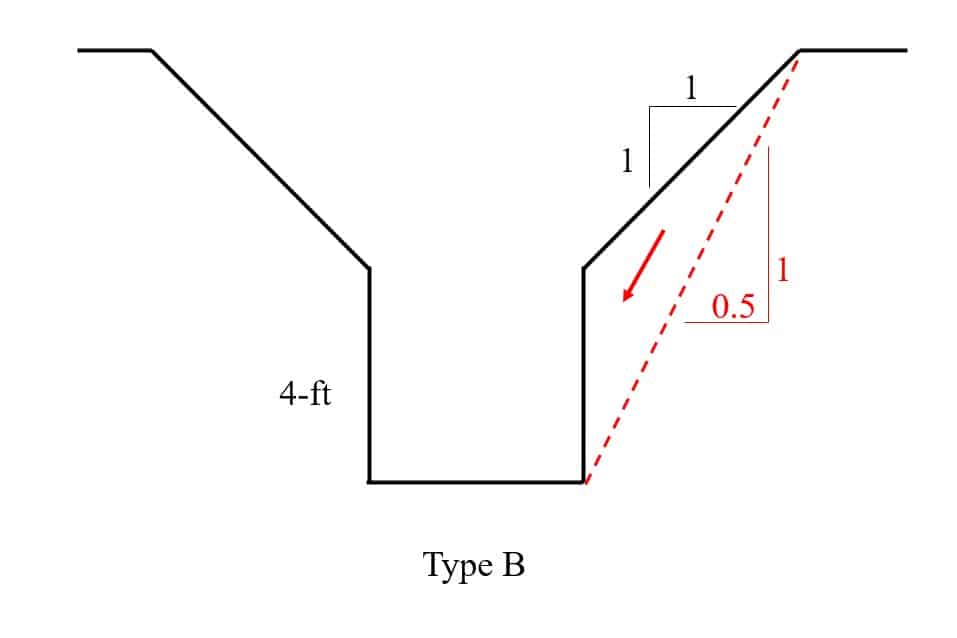

So is this safe?

Most definitely this is NOT safe. The soil in this trench could slide at a 0.5(H):1(V) angle into the trench, crushing a worker in the excavation. Yes…I chose the work crushing rather than trapping. The soil crushes victims causing serious internal injuries or death.

Deep Excavation Mistake #2. DIY for excavations deeper than 20′.

Excavations deeper than 20′ require an engineer’s design. OSHA only allows the competent person to determine the slope angle for excavations that are 20′ or less. If you need to go deeper than 20′, hire a licensed geotechnical engineer to design the slope. Once an engineer is involved, she may determine through lab testing or other data that the soil can be sloped steeper than you thought, saving you money!

Deep Excavation Mistake #3. I need to cut it to see it.

We have a term for certain cuts. We call them ABCs – “already been cut”. Why would someone excavate the full depth then decide they need their deep excavation shored? Many times I’ve been told, “I had to cut it to see it.” I think this comes from 2 things, uncertainty of the ground conditions and not checking the geometry prior to starting the deep excavation.

I’ve shown up on many sites to only have to ask the client to fill the excavation back to within 5′ of the ground surface so that we can being installing shoring. This can be avoided by test pits to determine the ground conditions prior to starting mass excavations. You can also check the geometry by asking 2 simple questions. How deep am I excavating and how much horizontal room do I have for sloping?

Deep Excavation Mistake #4. We’re going to build it really fast.

While this one may seem really silly to some, unfortunately, I’ve also heard this one too many times. There’s a sense that if I’m able to work quickly in front of the vertical cut, then everything will be ok. Certainly, an exposed cut can become more unstable over time, especially with changes in water content of the soil. However, would you gamble the safety of your employees or subcontractors on “doing things fast?”

I think we can all think of times in our careers when we’ve seen experienced contractors take risks, particularly with deep excavations, that they would never allow their loved ones to take.

Deep Excavation Mistake #5. I don’t have it in my budget.

Sometimes we miss something in our budget and shoring a deep excavation is not included. It’s not always the estimators fault either. Perhaps a utility or structure was built at a higher elevation and now there’s not sufficient horizontal room to slope per OSHA standards.

If possible, determine if the cause of shoring was due to direction from another party or unknow conditions. One example is an unknown utility that will require relocating expense or hiring a shoring contractor to excavate safely.

Even if there is not a possibility to receive compensation, we must always do the right thing. As a dear mentor of mine says, there are two statements that will never stand in court, “I didn’t have time.” and “I didn’t have money.” With the implicit ending, “….to do things right.”

Extra credit